Helical Piles Installation and Demonstration

Helical Piles Installation and Demonstration

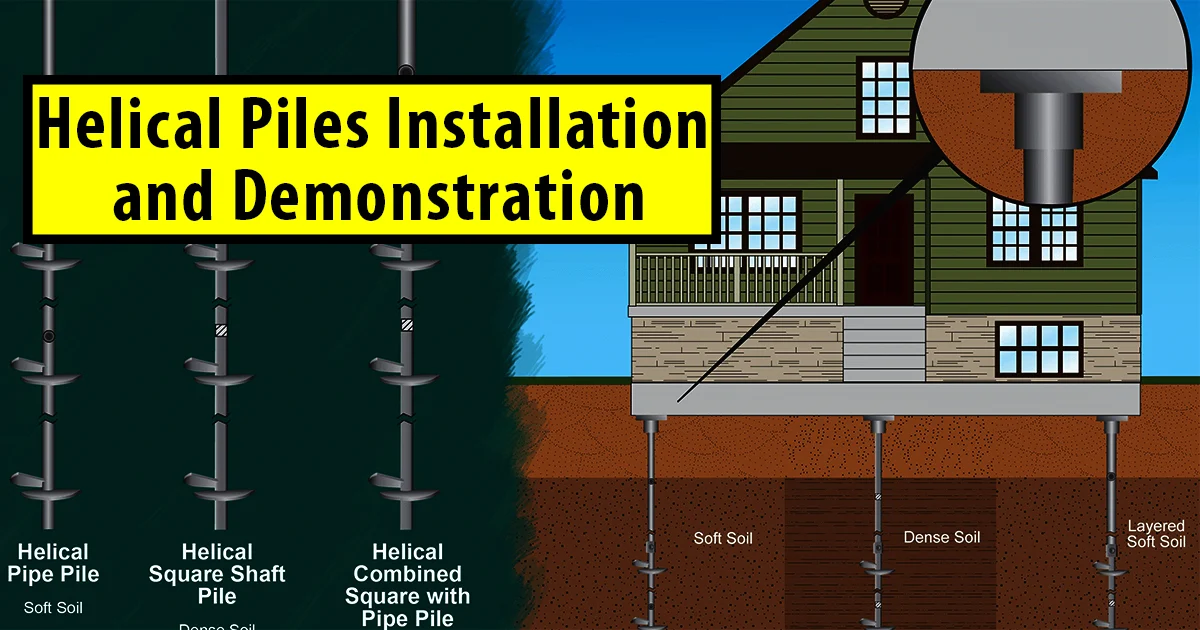

A helical piles consists of one or more helix-shaped bearing plates attached to a central shaft,which is installed by rotating or “torqueing” into the ground.Each helix is attached near the tip,is generally circular in plan,and formed into a helix with a defined pitch.Helical anchors/piles derive their load-carrying capacity through both end bearing on the helix plates and skin friction on the shaft.

Helical Piles

The GTL Helical (screw)Pile foundation is an innovative and sustainable foundation solution.The helical pile, also incorrectly referred to as a screw pile, consists of a central hollow shaft of various diameters and sectional thickness, with helical plates strategically welded at given spacing.

Design depth is achieved by mechanically connecting additional shaft sections of differing lengths which are normally governed by equipment and site restrictions.The helixes are rotated into the ground to a pre-designed depth.Each helical plate on any single pile will be of the exact same pitch as one another,which minimises soil disturbance during installation compared with conventional piling techniques.The diameter of the helical plates are governed by the pre-determined loading and soil conditions.Loads are transferred to the soils by the helical plates and shaft friction.The overall number and spacing of the plates are designed to maximise the allowable load capacity of the soils.

The technology of the GTL helical pile foundation is not so much in the manufacturing of the product but rather in the specific engineering design, with the foundation being designed as a solution to a particular requirement or condition.

Helical piles are referred to as small displacement piles and designed in accordance with International Standards or to the standards relevant to a specific country.

See More Underpinning

Extendable Helical Pile –Either Square or Round Shaft

No More Than 6 Helices Per Anchor

Foundation Underpinning

Foundation Underpinning with Helical Pile

Screw Foundation Installation with Portable Installer

Installation

The Helical (screw) pile is rotated into the ground by means of a bi-directional auger,hydraulically powered by an excavator or similarhydraulic powered equipment.Throughout the installation process GTL monitors the installation torque and pile alignment. Installation can be undertaken anywhere that you can accommodate an excavator or hydraulic equipment i.e. crane, forklift etc

Installation over water can be performed from a barge, floating pontoon and an engineered platform, as we designed for Brighton Pier.GTL monitor the installation torque for the following reasons:

- To provide a qualitative assessment of the soils being penetrated at various depths.The recorded installation torque and depth will be interpreted against the existing soil data, by way of a graph. By interpreting the soil data against the installation torque, a correlation can be obtained that enables a simple verification strategy to be determined.

- To maintain the integrity of the Helical (screw) pile during installation and to mitigate damage through exceeding torsional strength to any of the pile’s components.Each Helical (screw) pile has a maximum stress level and this must not be exceeded.

Book to read Pile Design and Construction Practice

Foundation Underpinning with Helical Piles

Repair Brackets

Raising Building with Repair Brackets

Advantages – Helical Piles & Anchors

Quick, Easy Turnkey Installation

• Immediate Loading

• Small Installation Equipment

• Pre-Engineered System

• Easily Field Modified

• Torque-to Capacity Correlation

• Install in Any Weather

• Solution for:

– Restricted Access Sites

– High Water Table

– Weak Surface Soils

• Environmentally Friendly

• No Vibration

• No Spoils to Remove

• No Concrete