PERVIOUS CONCRETE

PERVIOUS CONCRETE

- INTRODUCTION

Pervious concrete which is also known as no fines, porous, gap graded, and permeable concrete and enhance porosity concrete has been found to be a reliable storm water management tool. By definition, pervious concrete is a mixture of gravel or granite stone, cement, water, little to no sand (fine aggregate). When pervious concrete is used for paving, the open cell structures allow storm water to filter through the pavement and into the underlying soils. In other words, pervious concrete helps in protecting the surface of the pavement and its environment.

Pervious concrete has the same basic constituents as conventional concrete that is 15% -30% of its volume consists of interconnected void network, which allows water to pass through the concrete. High range water reducer and thickening agent are introduced in the concrete to improve its strength and workability. It can allow the passage of 0.014-0.023 m3 of water per minute through its open cells for each square foot 0.0929 m2 of surface area which is far greater than most rain occurrences. Pervious concrete is rough textured, and has a honeycombed surface, with moderate amount of surface ravelling which occurs on heavily travelled roadways. Carefully controlled amount of water and cementitious materials are used to create a paste. The paste then forms a thick coating around aggregate particles, to prevent the flowing off the paste during mixing and placing. Using enough paste to coat the particles maintain a system of interconnected voids which allow water and air to pass through. The lack of sand in pervious concrete results in a very harsh mix that negatively affects mixing, delivery and placement. Also, due to high void content pervious concrete is light in weight (about 1600 to 1900kg/m3). Pervious concrete void structure provides pollutant captures which also add significant structural strength as well. It also results in very high permeable concrete that drains quickly.

Pervious concrete can be used in a wide range of applications, although its primary use in pavements which are in: residual roads, alleys and driveways, low volume pavements, low water crossings, sidewalks and pathways, parking areas, tennis courts, slope stabilization, sub-base for conventional concrete pavements etc.

Pervious concrete system has advantages over impervious concrete in that it is effective in managing run-off from paved surfaces, prevent contamination in run-off water, and recharge aquifer, repelling salt water intrusion, control pollution in water seepage to ground water recharge thus, preventing subterranean storm water sewer drains, absorbs less heat than regular concrete and asphalt, reduces the need for air conditioning. Pervious concrete allows for increased site optimization because in most cases, its use should totally limit the need for detention and retention ponds, swales and other more traditional storm water management devices that are otherwise required for compliances with the Federal storm water regulations on commercial sites of one acre or more. By using pervious concrete, the ambient air temperature will be reduced, requiring less power to cool the building. In addition, costly storm water structures such as piping, inlets and ponds will be eliminated. Construction scheduling will also be improved as the stone rechargebed will be installed at the beginning of construction, enhancing erosion control measures and preventing rain delays due to harsh site conditions. Apparently, when compared to conventional concrete, pervious concrete has a lower compressive strength, greater permeability, and a lower unit weight (approximately 70% of conventional concrete). However, pervious concrete has a greater advantage in many regards. Nevertheless, it has its own limitation which must be put in effective consideration when planning its use. Structurally when higher permeability and low strength are required the effect of variation in aggregate size on strength and permeability for the same aggregate cement ratio need to be investigated.

- PREPARATION OF PERVIOUS CONCRETE

CONSTITUENTS OF CONCRETE

If a constituent is to be suitable for a particular purpose, it is necessary to select the constituent materials and combine them in such a manner as to develop the special qualities required as economical as possible. The selection of materials and choice of method of construction is not easy, since many variables affect the quality of the concrete produced, and both quality and economy must be considered. The characteristics of concrete should be evaluated in relation to the required quality for any given construction purpose.

2.1 CEMENT

Ordinary Portland cement, 53 grade conforming to IS: 269 – 1976. Ordinary Portland cement, 53 grade was used for casting all the specimens. Different types of cement also will produce concrete have a different rates of strength development. The choice of brand and type of cement is the most important to produce a good quality of concrete. The type of cement affects the rate of hydration, so that the strengths at early ages can be considerably influenced by the particular cement used.

2.2 COARSE AGGREGATE

Locally available crushed blue granite stones conforming to graded aggregate of nominal size 12.5 mm as per IS: 383-1970. Several investigations concluded that maximum size of coarse aggregate should be restricted in strength of the composite. In addition to cement paste – aggregate ratio, aggregate type has a great influence on concrete dimensional stability.

2.3 WATER

Casting and curing of specimens were done with the portable water which is available.

- 3. STRUCTURAL PERFORMANCE OF PERVIOUS CONCRETE

For the evaluation of the structural performance of the pervious concrete in civil engineering construction, the effects of varying the aggregate size on thecompressive strength and permeability and durability of pervious concrete were studied. This study covers the simple use of pervious concrete as pavement material in the construction of pedestrian walkways and parking lots.

3.1 PREPARATION OF TEST SPECIMEN

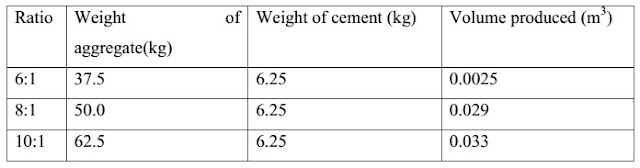

Three batches of test specimen were produced from each of the aggregate size representing aggregate cement ratios of 6:1, 8:1 and 10:1 with no fines in the mixes. The materials were batched by weight as in Table3.1. As earlier stated, two different sizes of coarse aggregate (crushed stone or granite) were used in this study. The sizes are 3/8-inch (9.375mm) and 3/4-inch (18.75mm) granite. The specific gravity test carried out on the two aggregate sizes gave average value of 2.7. For the two aggregate sizes, the mix proportions were done by weight. From each of the batches, 8 of 150mm concrete cubes were taken. The mix proportioning are as shown in Table 3.1.

Table 3.1 Mix Proportion by Weight of Aggregate and Cement

The batched materials are thoroughly hand-mixed with water so as to obtain uniform and homogenous pervious concrete. Water/cement ratio of 0.4 was added to form a cement paste, ACI 211.3R (2002) stipulates that the ratio should be between 0.35 and 0.45. A total of 24 cubes were produced for each aggregate size for different mix ratio of 6:1, 8:1 and 10:1 of coarse aggregate and cement.