Slabs and their Supports

Slabs and their Supports

Slabs are surface plane elements that bear loads transverse to their plain.Most of the times, slabs are statically indeterminate elements that consequently redistribute the stresses applied to them. This ability makes them highly secure against bending and shear failure. Cantilevers are excluded since slabs which are statically determinate elements and therefore need special care in their construction.

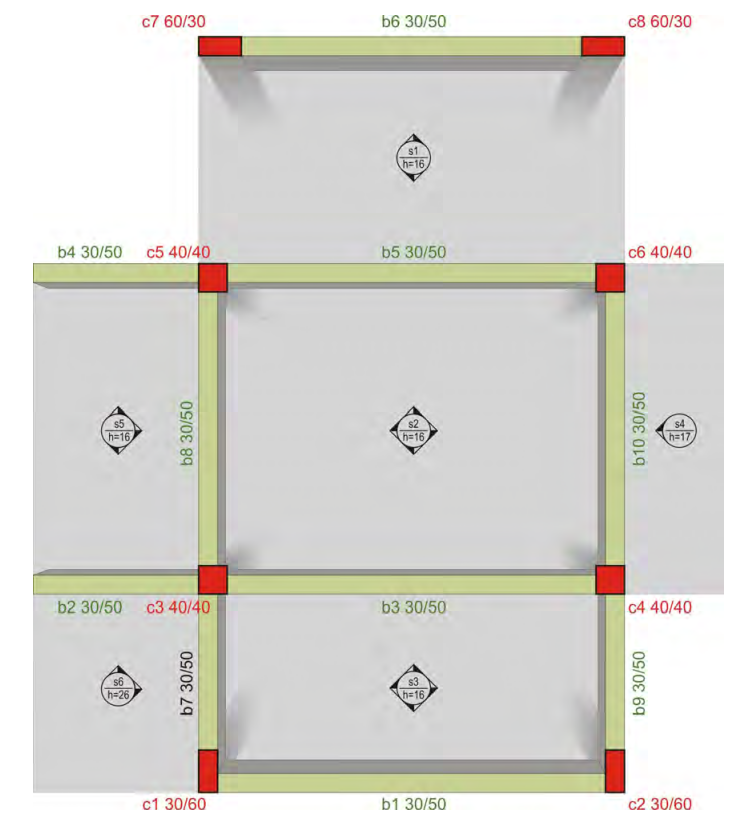

Slabs are separated into categories dependent on their supports:

One-way slabs (Simply supported)

They are those supported on two out of four, opposite sides like Π1 of the above example.

Two-way slabs

They are those supported on all four sides like Π2, Π3 of the above example

Cantilever slabs

They are those with a fixed support on only one out of four sides, like of the above example.

Two-way three support slabs

They are those supported on three out of four sides, like of the above example.

Two-way two support slabs

They are those supported on two adjacent sides, like Π6 of the above example.

The above categorization regards rectangular slabs and is applicable only when the side supports are clearly defined in their full length. When a slab has a general polygonal shape it can be approximately simulated as a similar orthogonal shaped slab.

The slab’s essential thickness is determined according to the required flexural and shear strength capacity as well as to the limitations of the allowable deflections. Usually the determinative factor is the second parameter because the slab’s elastic stability (stiffness) is important throughout the entire service life of the structure. Its lack can even become apparent with human walking as it may initiate vibrational motion.

As regards to support, the safest slab is the two-way slab and the most vulnerable is the cantilever slab. This happens because in a two-way slab, potential loss of one support results in a two-way three support slab, while in the case of a cantilever slab potential support loss results in collapse.

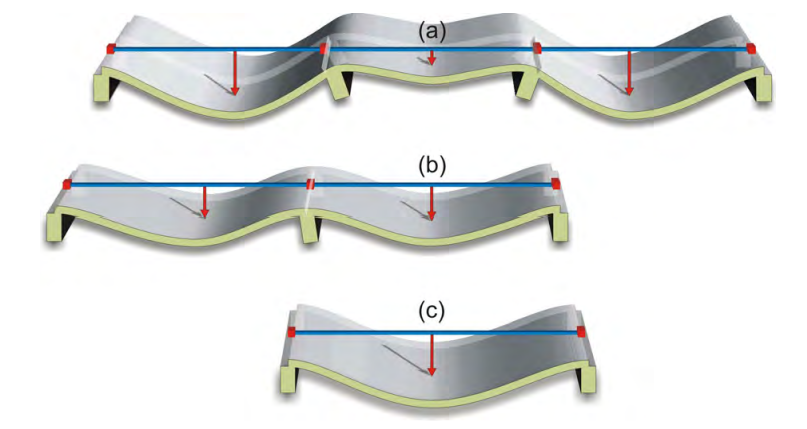

Slabs behave better when having one adjacent slab and even better when having two adjacent slabs in both directions.

The following picture shows deformations, in a large scale but proportionate to one another, for three different types of slab continuity. It is obvious that continuous slabs suffer lighter deflections thus they have better elastic stability (stiffness).

The slab with the bilateral continuity (a) behaves in the best way. Next comes the slab with the unilateral continuity (b) while last comes the slab with no continuity.

In common structures, for slab thickness equal to 15cm, the slab’s span may vary between 3.60m and 6.00m and the cantilever spans may be up to 1.50m. For slab thickness equal to 20cm the slab’s span may range from 4.80m to 8.0m and the cantilever spans may be up to 2.0m.

The 15cm thick slab has a self weight equal to 0.15m*25 kN/m³=3.75 kN/m² while the live load due to human use, furniture etc that it is called to bear, is equal to 2.0 kN/m² only. If the slab has a thickness equal to 20cm its self weight is 5.0 kN/m², and if it is equal to 30cm its self weight is 7.50 kN/m² whereas the live loads remain the same.

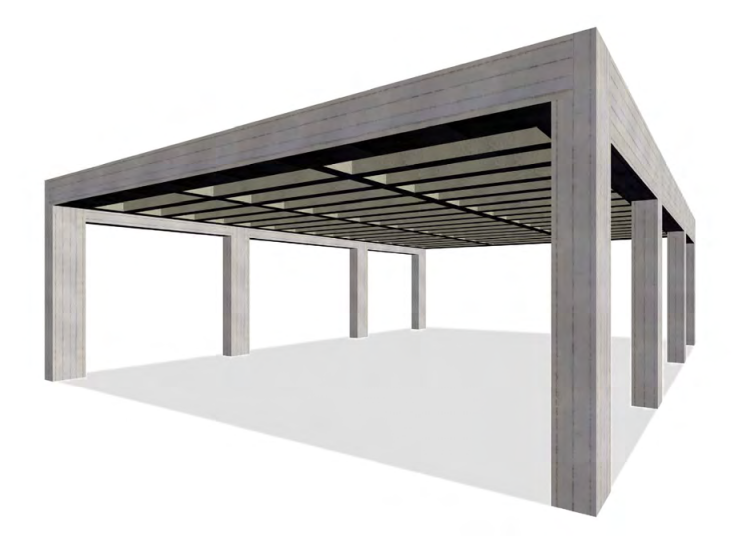

Therefore for large spans ribbed slabs (waffle slabs) (Zoellner, sandwich) can be used, like the one shown in the figure below. A ribbed slab with total thickness of 30cm may have a self weight equal to 3.75kN/m², which corresponds to the self weight of a 15cm thick solid slab.

Advantages of ribbed slabs:

– their large effective thickness provides them with a high level of elastic stability (stiffness),

– they have low dead weight consequently they apply relatively light stresses,

– they do not overload the structural frame and the foundation,

– because of their large effective thickness they comparably need lesser amount of reinforcement

Disadvantage of ribbed slabs:

– Their construction is more challenging and therefore they require meticulous reinforcement detailing.

A one-way (simply supported) ribbed slab, in the primary direction is composed by usual ribs while in the secondary direction the ribs are vertical and sparsely placed thus ensuring the even load distribution.

The voids between the ribs are usually covered with extra light-weight polystyrene with a density of e.g. 25kg/m³ (compared to the density of the reinforced concrete that is equal to 2500kg/m³)

Usually two-way slabs have square voids between the ribs because the demand for adequate bending strength is equal in both directions. The square voids are being shaped either with the use of light-weight fillings like polystyrene or with the use of plastic moulds. The later have significant constructive advantages (qualitative, fast construction) thus providing proportional economical solutions.